Bolts iQ™

To meet the growing need for electricity, the global transition to renewable energy is accelerating rapidly, with worldwide wind capacity estimated at 744 Gigawatts in 2021*. With exponential growth projected, properly maintaining the growing number of deployed wind turbines is of critical importance to renewable energy operators and OEMs alike. In keeping with our tradition of innovation in the application of nondestructive testing techniques, FDH is addressing the critical need for novel approaches to maintenance in the renewable energy industry.

Introducing the Bolts iQ™ Measurement Tool

A key maintenance program imperative is maintaining the correct tension in the thousands of bolts contained in a typical wind tower. This is critical to ensuring the integrity and stability of these assets over time in response to both normal wear and tear and environmental factors. Traditional tensioning methods, such as hydraulic jacks, are inherently inaccurate, inefficient, and unwieldy, resulting in increased operational downtime and higher costs associated with bolted joint installations and inspections. Current methods require tension modification by torque or hydraulic force, which can unnecessarily alter the current tension, often resulting in bolt overtightening. Also, more recent inspection methods typically require the technician to know the unstressed length in advance in order to make an accurate assessment of tension.

Bolts iQ, a faster, safer, and more accurate solution for measuring flange bolt tension, is projected to be available in late 2023.

*Worldwide Wind Energy Association

A faster, safer, more accurate solution for measuring bolt tension

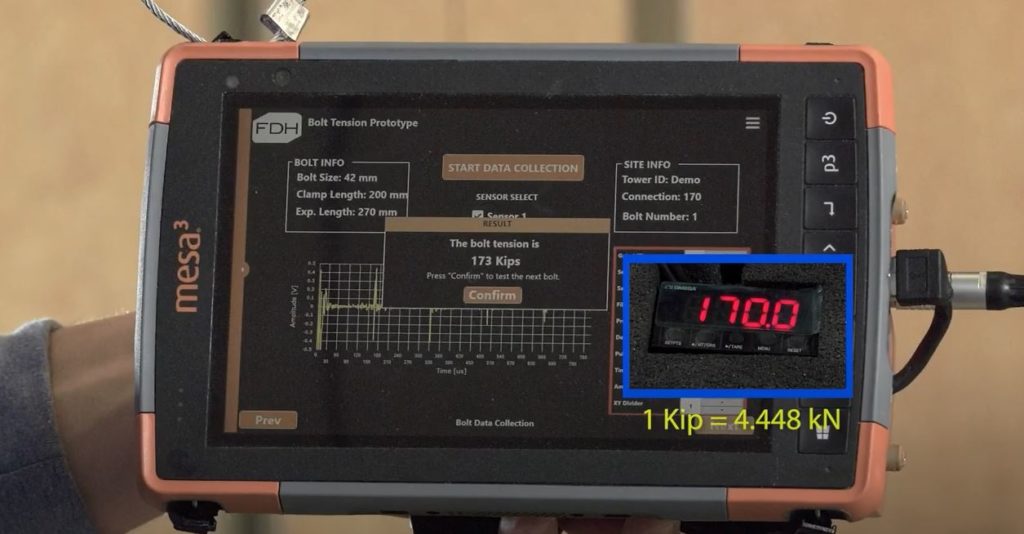

The Bolts iQ system in development provides fast and accurate direct tension measurement using FDH’s patented ultrasonic sensing technology. This handheld measurement tool provides immediate tension readout with pass-fail indication and alerts as part of an IIoT solution that enables secure, cloud-based data management, maintenance planning, reporting, and analytics.

Advanced machine learning and process automation ensures quality data is collected with minimal technician training and offers more accurate tension predictions on previously untested bolts. Cloud-enabled historical data can be used to develop optimized predictive and proactive maintenance and inspection processes.

Safe, reliable, accurate results with minimized service interruptions

This novel approach can potentially reduce labor costs, inspection time, and heavy equipment requirements while improving tension prediction accuracy by a factor of three or more over traditional methods.

A prototype in advanced testing phase, the Bolts iQ measurement tool is currently being trialed in various applications. FDH is seeking additional partners, including wind farm owners, operators, and inspection service providers, to participate in field trials to help provide crucial customer input to the product development process.

Please contact us today to learn more about Bolts iQ or if you would like to participate in one of our field trials.

Download the Bolts iQ Solutions Brief

See the Bolts iQ Prototype Lab Demo

Download the Bolts iQ Presentation (include this too?)

Copyright 2024 FDH Infrastructure Services. All Rights Reserved. Privacy Policy | Terms of Use