Nondestructive Testing

FDH is a pioneer in the nondestructive evaluation (NDE) of critical structures. The firm’s research and development of electromagnetic and dispersive wave propagation (DWP) techniques has led to the award of three U.S. patents and multiple proprietary analysis techniques. FDH’s nondestructive test (NDT) methods have been applied to tower structures, wind turbines, water tanks, bridges, dams and levees.

Data that Drives Decision Making

FDH’s proprietary NDT methods generate the data necessary for enhanced decision making about managing and extending the lifespan of the nation’s aging infrastructure. Clients utilize our technologies when as-built drawings may not exist, new construction needs verification, or when failures have occurred. Our expertise results from more than two decades of research and over 25,000 investigations of critical structures and their foundations.

FDH’s proprietary NDT methods generate the data necessary for enhanced decision making about managing and extending the lifespan of the nation’s aging infrastructure. Clients utilize our technologies when as-built drawings may not exist, new construction needs verification, or when failures have occurred. Our expertise results from more than two decades of research and over 25,000 investigations of critical structures and their foundations.

NDT Services

FDH specializes in the nondestructive evaluation of heavy civil structures (bridge decks and piers, dam spillways and anchorage systems, levees), towers (communication structures, transmission towers, wind turbines), and building infrastructure (residential, commercial, and industrial). To request a quote or for more information: NDT@fdh-is.com

-

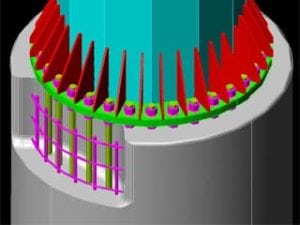

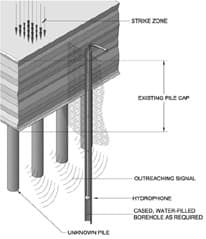

Unknown Foundations & Foundation Mapping

Unknown foundations are a major problem facing the owners of aging civil infrastructure. FDH specializes in bringing knowledge about what’s underground to the surface. For bridge structures, when as-built documentation no longer exists, this effort typically involves determining pile lengths using Bending Wave (BW) and Parallel Seismic (PS) methods. For communications and transmission towers, FDH can identify the as-built dimensions of a tower’s reinforced concrete pier foundations and map the foundations by physical probing and by conducting Ground Penetrating Radar (GPR), Impact-Echo (IE) and Dispersive Wave (DW) testing, using proprietary technology, to determine the depth/thickness of each concrete foundation type, plan dimensions, and specific geometry. For industrial plants preparing for renovations or upgrades, FDH can provide critical structural details of existing concrete foundations to identify conditions that may warrant repairs or additional reinforcement.

-

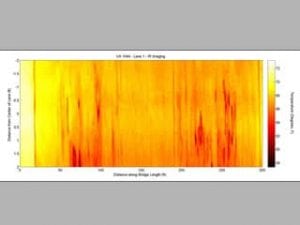

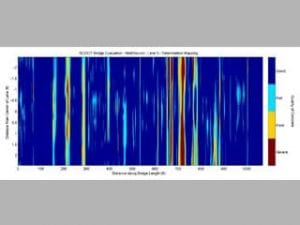

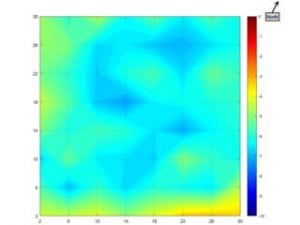

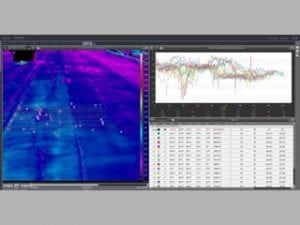

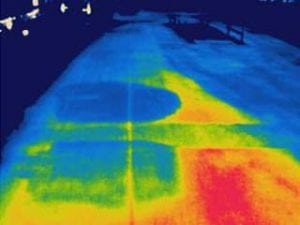

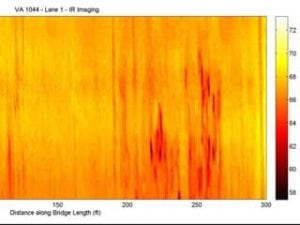

Rapid Bridge Deck Scanning

The combination of step-frequency Ground Penetrating Radar (GPR), high-resolution Infrared Thermography (IR), and digital imaging helps identify delaminations, corrosion, and pavement thicknesses in concrete bridge decks at high speeds. Paired with LIDAR mapping systems and proprietary data analysis and automation that utilizes FDH’s 30,000+ GPR records, FDH has developed a high-speed bridge deck assessment system that utilizes automated data fusion analysis for efficient and effective data processing. Data results support decision making for predictive maintenance, asset management, and the best options for prolonging the life of the structure.

-

Rebar Corrosion

Embedded rebar corrosion is a significant cause of cracking and deterioration in reinforced concrete structures. FDH uses a combination of NDT methods to identify reinforcement steel corrosion. Ground Penetrating Radar (GPR), Half-Cell Potential (HCP), and Dispersive Wave (DW) testing, among other inspection methods, assist with the identification of rebar corrosion and the level of corrosion risk for various environmental conditions.

-

Concrete Material Property

Nondestructive test methods can be utilized to identify fundamental properties of concrete. Ultrasonic Pulse Velocity (UPV) is the most effective NDT method for evaluating concrete (compressive) strength and identifying subsurface defects. Wenner Four-Electrode Method is one of the most reliable methods for measuring concrete resistivity. Rapid Chloride Penetration is an in-situ method of measuring concrete chloride content. Concrete PH, concrete resistivity, and concrete chloride contents are electrochemical key parameters that directly affect corrosion of steel embedded in concrete.

-

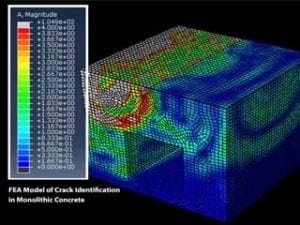

Crack Investigations

Large monolithic concrete and other concrete structures are susceptible to hidden cracks and other defects that can compromise the integrity of the structure due to internal rebar/anchor rod corrosion. Using a combination of NDT methods, including visual inspection and Ultrasonic Pulse Velocity (UPV) testing (to identify surface cracks), Ground Penetrating Radar (GPR) (to identify major rebar defects within concrete), and Dispersive Wave (DW) propagation testing (to identify internal cracking), FDH can determine areas where there is a high probability of concrete deterioration, including internal cracking and delamination.

-

Failure Investigations

Foundation failures of critical structures, such as wind turbines, transmission towers, and telecommunications towers as well as building slabs and columns, can occur due to poor design, construction issues, soil conditions, additional loading, and deterioration. FDH employs a combination of inspection methods and nondestructive techniques to evaluate the condition of failed structures and their foundations as well as the tension and active corrosion of anchor bolts and embedded anchorages.

NDT Methods

FDH is a pioneer in the development of electromagnetic and dispersive wave propagation techniques for concrete decks and foundations, as well as post-tensioned steel anchorages. In addition to its patented test methods and proprietary data analysis techniques, FDH uses a wide array of NDT methods, sometimes in combination for improved accuracy, for critical structure investigations. To request a quote or for more information: NDT@fdh-is.com

-

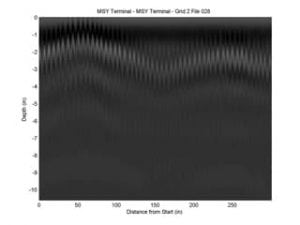

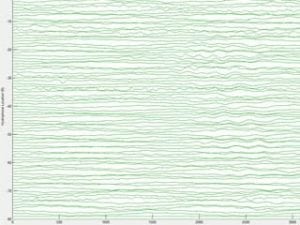

Dispersive Wave Propagation / Bending Wave

The Dispersive Wave (DW) propagation method was first pioneered in 1994 by FDH founders at North Carolina State University for the North Carolina Department of Transportation and Federal Highway Administration. The research was driven by the fact that several thousand bridges existed with timber piles of unknown lengths, and a safe, nondestructive method was needed to address the problem. The DW method, which collects and evaluates stress wave data using a proprietary analysis method, has been adapted and validated for timber and concrete piles, as well as other critical structures. The method has resulted in significant cost savings to federal and state agencies.

-

Ground Penetrating Radar/Structure Scanning

GPR is a geophysical method that uses electromagnetic pulses in the radar and microwave section of the frequency spectrum to detect anomalies in underground utilities and concrete substructures. Engineers use the data to locate/analyze subsurface artifacts, such as pipelines, drums, old foundations, storage tanks, and erosion voids. Step-frequency GPR differs from traditional GPR in that it sweeps across multiple frequencies in the electromagnetic spectrum, allowing for the measurement of multiple layers of material simultaneously, such as the thickness of pavement layers in a bridge deck. Structural scanning (SS) generates 3D images of steel reinforcement found within concrete structures. The images can represent a target’s location and properties and allow engineers to perform detailed capacity calculations of the structural members.

-

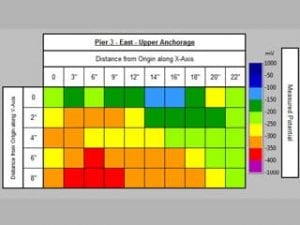

Half-Cell Potential

HCP testing identifies the corrosion activity of reinforcing steel in concrete structures. The test method is based on the principle that during the electrochemical corrosion reaction an electric potential difference is generated in the reinforcing steel. FDH conducts HCP testing using a device manufactured by Proceq SA. This device uses an electrode consisting of a copper rod immersed in a saturated copper sulfate solution, which maintains a constant potential. This electrode is moved across the concrete surface over the steel target of interest in a grid pattern, in order to ascertain the strength of an electrical field throughout. Upon comparison of these values with a reference, the extent of the corrosion potential can be estimated on the underlying steel.

-

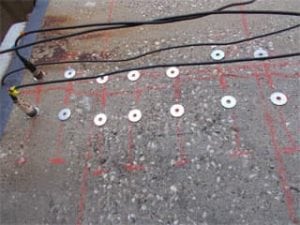

Impact-Echo

IE testing is a special form of stress wave NDT that can help determine concrete thickness and the presence of internal defects or cracks. FDH’s custom IE method is conducted by temporarily mounting accelerometers (gages) on the top of a structure, such as a concrete foundation, and then striking the foundation with a series of impact devices. The compression waves created by the blow propagate up and down the foundation’s length with the accelerometer data being digitally recorded and stored using custom Data Acquisition (DAQ) hardware. The data is then analyzed by digital signal processing techniques using proprietary software developed and maintained by FDH. The analysis determines the time needed for compression waves to travel from the impacted surface to the bottom of the concrete (or a significant change/defect) and return. The foundation’s depth is then calculated from computed wave speed and the corresponding time required for travel.

-

Infrared Thermography

IR involves imaging of energy patterns via remote sensing cameras, positioned for ground use (walking, driving) or aerial use (drone). Infrared cameras measure the thermal radiation emitted from a structure depending on the thermal properties of the material and its size and shape. Used properly, thermal imaging can detect corrosion damage, delaminations, voids, and inclusions as well as many other detrimental conditions. IR data is used to analyze energy patterns emitted from a structure.

-

Parallel Seismic/Dispersive Side Sonic

A modern successor to the Parallel Seismic (PS) method, the Dispersive Side Sonic (DSS) test uses the concepts of Dispersive Wave (DW) propagation to analyze PS data when searching for pile tips that are difficult to locate with traditional analysis procedures. DSS involves positioning a transducer into a borehole at predetermined locations near a foundation element and generating a mechanical impact along an exposed portion of a structure. The data is collected and used for identifying the depth of the foundation’s tip by tracking individual frequencies within the time records. DSS has proven successful for finding pile tip locations from deeply buried steel piles and piles supported by footings. It has been employed on other foundation types, such as timber piles, concrete piles, drilled caissons, auger cast piles, and rock anchors.

-

Ultrasonic Pulse Velocity

The UPV method measures the velocity of stress waves traveling through concrete. Data results help indicate concrete strength and density. Ultrasonic stress waves are initiated at one face of a concrete member when a transducer is excited by high voltage pulses. This ultrasonic stress wave pulse travels through the concrete and is received at the opposite face of the concrete member by a similar transducer. This signal is amplified and can be displayed on an oscilloscope. Time measurement circuitry in the V-meter determines the elapsed time for the stress wave pulse to travel through the concrete. The pulse velocity of the concrete being tested is determined dividing the measured path length by the elapsed time measured by the V-meter.

Copyright 2024 FDH Infrastructure Services. All Rights Reserved. Privacy Policy | Terms of Use